Staple Fiber Market,(By Product: Solid, Hollow & Other. By Application: Apparel, Automotive, Home Furnishing, Filtration & Others. By Region - North America, Europe , Asia-Pacific , LAMEA) - Industry Analysis, Growth, Trends & Forecast, 2022 to 2032

Report Type : Syndicate Report

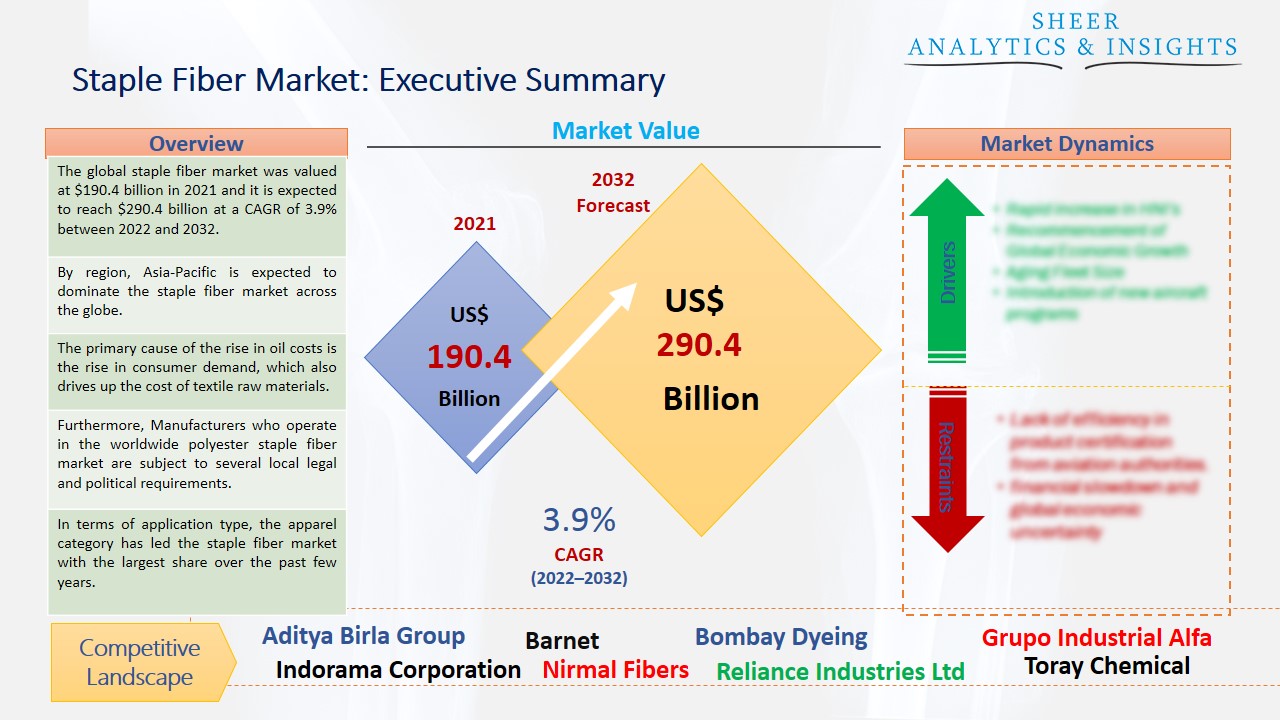

The global staple fiber market was valued at $190.4 billion in 2021 and it is expected to reach $290.4 billion at a CAGR of 3.9% between 2022 and 2032. Over the course of the projected period, the market is anticipated to be driven by growing application industries in Asia Pacific and rising demand for sustainable textiles. Because of the features of the product, demand is anticipated to rise in the near future, promoting industry growth.

By region, Asia-Pacific is expected to dominate the staple fiber market across the globe.

Staple fiber spinning is a combination of staple fiber components used in the apparel industry to alter yarn properties. For example, acrylic fibers are used in small amounts in the yarn used to weave woolen sweaters to strengthen the yarn's resilience to wear and friction. To attain a specific level of electrical conductivity in smart textiles, a specific quantity of electrically conductive staple fibers can be incorporated into the yarn. In addition, Purified Terephthalic Acid and Monoethylene Glycol, two downstream byproducts of crude oil, are frequently utilized as raw ingredients in the manufacture of polyester staple fiber. Therefore, the change in crude oil prices also affects the cost of raw materials for polyester staple fiber.

The primary cause of the rise in oil costs is the rise in consumer demand, which also drives up the cost of textile raw materials. Floods, power outages, and growing crude oil inventories are all pushing up crude oil prices. Moreover, one of the key growth drivers in the global market is the increased demand for recycled polyester staple fiber. Consumers are choosing sustainable textiles created from recycled materials more frequently. The supply of eco-friendly clothes in a variety of fashionable styles, vibrant hues, and eye-catching prints is also helping to meet consumer demand.

Source: SAI Research

Download Free PDF Sample Request

Furthermore, Manufacturers who operate in the worldwide polyester staple fiber market are subject to several local legal and political requirements. Over the forecast period, the regulations are expected to restrain the market growth. Staple fiber imports from China were subject to significant price depressions as well as price suppressions in Indonesia. The increase in polyester staple fiber production capacity in China, Taiwan, and India is a sign that there is an excess in these nations.

One of the easily understood components of the textile business is staple fiber. It is a synthetic fiber produced by high-output, high-efficiency, spinning lines that can produce 50–300 tons per day. It is a flexible form of fiber with uses in a range of end-use industries, including filtration, textiles, home furnishings, and the automobile industry. Staple fibers are unprocessed natural fibers from plants or animals, such as unbleached cotton, wool, hemp, and flex that may be twisted into yarn. As a filament yarn, silk is an exception to the rule for staple fibers. To increase strength, filaments given from diverse sources are heated, cooled, and crimped. Hence, these rising factors are expected to drive the growth of the market over the forecast period from 2022 to 2032.

Based on product type, the solid segment accounted for the largest share of this market. Over the next eight years, the market is anticipated to be driven by the expanding textile manufacturing sector, especially in the emerging economies of many regions. One of the main elements influencing PSF's demand is its superior qualities over cotton, its alternative. One of the main elements influencing PSF's demand is also its advantages over cotton, its alternative. However, the hollow segment is also anticipated to propel the market growth during the forecast period from 2022 to 2032. It improves the overall quality of walls, tanks, and other pre-cast items including tiles, manhole covers, and blocks in addition to filling in gaps in the concrete. Thus, the expansion of the worldwide building industry supports the demand for fiber.

In terms of application type, the apparel category has led the staple fiber market with the largest share over the past few years and is also anticipated to drive market growth over the forecast period. Activewear, sportswear, and intimate apparel are all part of the apparel market. Consumers are increasingly choosing sustainable fashion, which is defined as clothing made from polyester staple fiber, as textile technology develops. Additionally, cotton and polyester fibers have a low environmental effect, less pilling, and enticing softness. Due to its affordability, strength, lightness, and wrinkle-free qualities as well as its adaptability as a weaving, knitting, and knitting-blend fabric, polyester has surpassed cotton as the most popular fiber.

Geographically, the Asia-Pacific region is expected to hold its dominant position over the forecast period. Significant market companies like Shanghai Polytex Co., Limited, Teijin Frontier Co., Ltd., China Petrochemical Corporation, Reliance Industries Limited, and others are predicted to improve market revenue growth in the area, contributing to the industry's rapid growth rate. Additionally, the region's developing economies, such as Taiwan, South Korea, China, and India, have also experienced rapid economic expansion.

According to the study, key players such as Aditya Birla Group (India), Barnet (Germany), Bombay Dyeing (India), Celanese (U.S), Grupo Industrial Alfa (Mexico), Indorama Corporation (Singapore), Lenzing AG (Austria), Nirmal Fibers (India), Reliance Industries Ltd (India), Shanghai Polytex Petrochemical (China), SASAC (China), Toray Chemical (South Korea), Unitec Fibers (India), Huvis (South Korea), Xinda (Taiwan), among others are leading the global staple fiber market.

Scope of the Report:

| Report Coverage | Details |

| Market Size in 2021 | US$ 190.4 Billion |

| Market Volume Projection by 2032 | US$ 290.4 Billion |

| Forecast Period 2022 to 2032 CAGR | 3.9% |

| Base Year: | 2021 |

| Historical Data | 2019, 2020 and 2021 |

| Forecast Period | 2022 to 2032 |

| Segments covered |

By Product Type: Solid, Hollow & Other By Application Type: Apparel, Automotive, Home Furnishing, Filtration, Personal Care and Hygiene & Others |

| Geographies covered |

North America, Europe, Asia-Pacific, LAMEA |

| Companies covered | Aditya Birla Group (India), Barnet (Germany), Bombay Dyeing (India), Celanese (U.S), Grupo Industrial Alfa (Mexico), Indorama Corporation (Singapore), Lenzing AG (Austria), Nirmal Fibers (India), Reliance Industries Ltd (India), Shanghai Polytex Petrochemical (China), SASAC (China), Toray Chemical (South Korea), Unitec Fibers (India), Huvis (South Korea), Xinda (Taiwan), among others. |

The Global Staple Fiber Market Has Been Segmented Into:

The Global Staple Fiber Market – by Product Type:

- Solid

- Hollow

- Other Types

The Global Staple Fiber Market – by Application Type:

- Apparel

- Automotive

- Home Furnishing

- Filtration

- Personal Care and Hygiene

- Others

The Global Staple Fiber Market – by Regions:

- North America

- The U.S.

- Canada

- Mexico

- Europe

- The U.K.

- France

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- India

- China

- Japan

- Australia

- Rest of Asia Pacific

- LAMEA

- Middle East

- Saudi Arabia

- UAE

- Others

- Latin America

- Brazil

- Chile

- Others

- Africa

- South Africa

- Egypt

- Others

Buy Chapters or Sections

Customization options available to meet your custom research requirements :

- Request a part of this report

- Get geography specific report

- Request historical analysis

- Check out special discounted pricing